Powder soot bulk loader

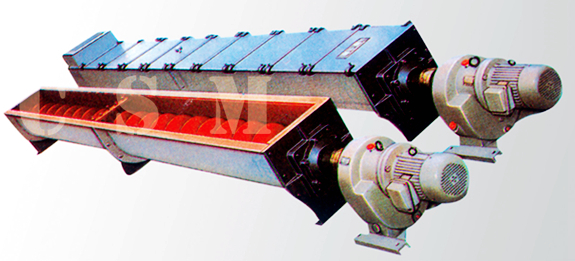

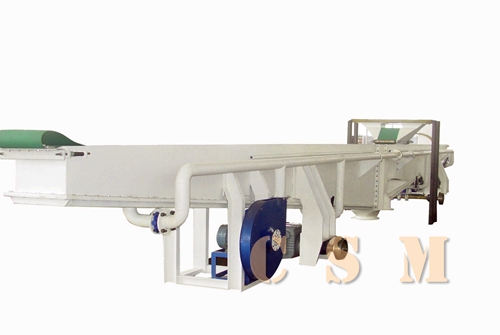

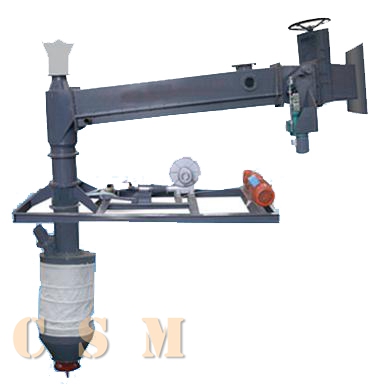

Powder soot bulk loader is used mainly as the powder soot bulk loading of electric power station and cement bulk loading of cement industry. The main characteristic which is different from the general bulk loaders is that the materials are separated from the drawing mechanism fully. This advantage can not only improve the efficiency of running and durability of equipment, but also facilitate the dust filtering. This equipment, discharging device, air slide,vibration hopper and other feeders are combined to become an automated bulk loader up to truck and ship with a fully automatic control system. The entire process is conducted in the sealed state, which is effective to prevent dust from escaping.

Main structure and working principle

1.Scalable bulk loader

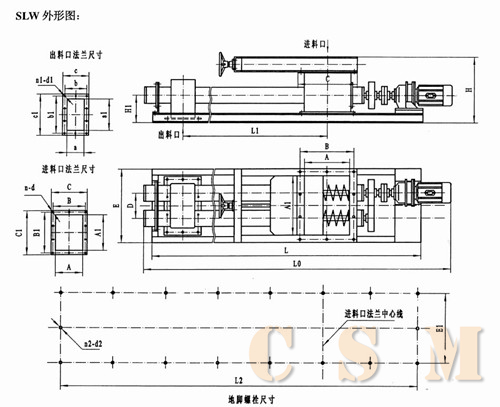

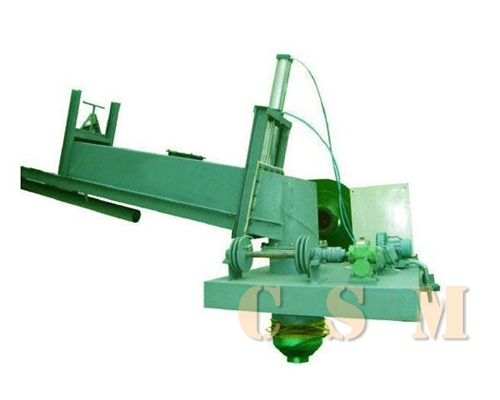

Powder soot bulk loader is composed of transmission frame, hoisting device, transmission device, losing rope device, channel steel block, level meter, filtering fan, the discharging pipe, filtering tubes and bulk head. The material flows into the tank through the discharging pipe based on its deadweight. The dust between the discharging pipe and filtering tube is sucked into filtering bag or ash silo by the filtering fan. The discharging pipe and filtering tube is scalable. Bulk head movement is achieved by the hoister driving system, safety controlling devices and losing rope device with declining and increasing of the scalable tubes.

2. The declining head of the dry ash bulk loader has an outside liner of rubber layer which achieves a tight seal with the tanker inlet.

3. The declining head is biconical structure. After lifting, the material outlet will be automatically closed.

4. Level meter is equipped with the solid tuning fork limited switch which is imported. It is sensitive, accurate and reliable with good quality.Main technical parameters.

| Model |

SZJ-100A |

SZJ-150A |

SZJ-200A |

| Handling capacity t/h |

100 |

150 |

200 |

| Tube diameter Φmm |

219 |

273 |

325 |

| Suction pipe diameter Φ |

400 |

400 |

400 |

| Bulk Head mm |

1300~3000 |

| Bulk head lifting speed m/min |

6.6 |

6.6 |

6.6 |

| Dimensions mm |

2286×1050×900 |

| Total weight t |

0.85 |

0.9 |

0.95 |

| project |

SZJ-100A |

SZJ-150A |

SZJ-200A |

| discharging capacity t/h |

100 |

150 |

200 |

| discharging pipe diameter Φmm |

219 |

273 |

325 |

| inputting pipe diameter Φ |

400 |

400 |

400 |

| bulk loader head distance mm |

1300~3000 |

| lifting and falling speed of bulk loader head m/min |

6.6 |

6.6 |

6.6 |

| size(L*W*H) mm |

2286×1050×900 |

| total weight t |

0.85 |

0.9 |

0.95 |

Installation and Commissioning

1. After installed, empty running is carried out by manual operation firstly to observe theflexibility and stability of bulk loader head with its up and down driven by hoister device. If everything is running well, the next test step is followed.

2. The test of losing rope limit switch: the bulk loader head is declined to the max. distance to make it being sealed with the material tank of the truck. When the bulk loader head is declined further, the steel rope is in relaxation state, so the losing rope limit switch should send out a signal.

3. Bulk head end limit Switch commission: when the bulk loader head is lifted up to the limited suspension height, the up limited switch of hoist device sends out a signal to stop moving of bulk loader head.

Operation:

After delivery vehicles is in loading place, the bulk loader head is declined by the semi-automatic controlling devices. After the bulk loader head is sealed with the top part of truck inlet, automatic controlling device start to work, i.e. fan is open automatically; the upper feeder then is open to begin discharging material into the truck. When the material tank is full, level meter sends a signal and the top feeder is shut down automatically by the corresponding electric control and gas control system. After a short time delay (usually four to six seconds),filtering fan is shut down automatically and bulk head is lifted. A completed discharging process is finished finally.

Feeder and filtering fan are locked and closed mutually during loading and discharging process, i.e. when the implemented by former, the latter can not open or close. It is necessary to unlock the interlock to change the above sequence.

Attentions

1.When operating, the outlet of bulk loader head should be sure to align to mouth of the tank, otherwise there will be potential accidents of materials overflow.

2.When great dust emission suddenly happens during loading, it means that the process of exhausting material is not smooth. Stop loading immediately and not lift bulk loader head.

3.If the bulk loader head has been declined and wire rope is loosed, the hoister must be stopped in order to prevent any potential incidents caused by too loose rope. If the indictor light is not on when the bulk loader head has fallen to regulated position, it means the switch of losing rope is out of control. Stop feeding immediately, lift bulk loader head and exam it.

4.If the full time of loading is expired, but level meter doesn’t send a signal, stop discharging immediately, lift bulk loader head. The level meter may be out of order and need to be overhauled if the material silo is found to be full.

5.If material overflow happens during loading, stop loading immediately. Do not lift bulk loader head when it is full of materials until the filter tube is demounted and the material in the tube is removed.

6.Adjusting the length of wire rope to make sure a flexibility of the discharging pipe.Powder transportation equipment Powder transportation equipment is imported as it has the most advanced technology and function of similar equipments around the world. It applies negative pressure transport principle to send materials from one location to another through the pipeline. The entire process is completed in confined state entirely to stop any potential harm and pollution from dust to the work environment, the surrounding area and operators. It can be applied to the industries of pharmaceutical, food, chemicals and batteries.