Steel Slag Roller Press

Steel Slag Roller Press

Steel slag is a kind of by product generated in steel making and consists of complex and changeable components. The main chemical components include CaO, SiO2, Ai2O3, FeO2, Fe3O2, MgO, TO2, K2Q, Na2O, SO3, MnO, P2Q3, etc. and the main mineral components include tricalcium silicate, dicalcium silicate, monticellite, rhodonite, calcium aluminoferrite, calcium ferrite, RO and free calcium oxide, etc.

Due to great property difference, highly fluctuant components, high hardness and poor grindability, as well as 5-15% content of iron and 14-30% content of iron containing magnetic substance, the steel slag shows great difficulty in effective utilization. In addition, during steel making, slag output can occupy around 20% of the total steel output, thus the study of effective and simple steel slag utilization method has been taken into great consideration by many countries. The most important study is to increase the additional value of steel slag. In order to achieve this goal, the most effective way is that the ultra fine steel slag powder can be used as the mixed material of steel slag cement.

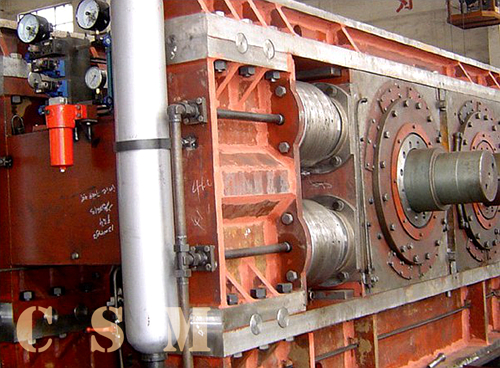

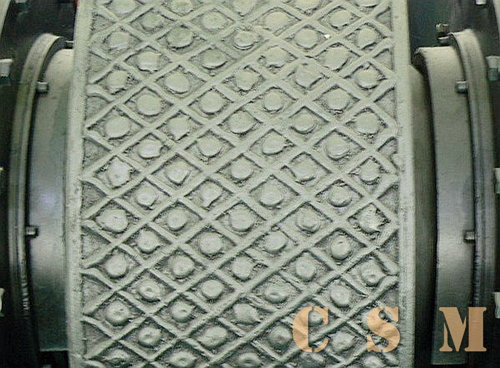

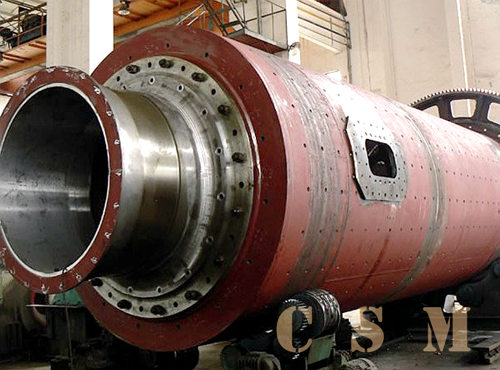

Through years of persistent practice, Haijian has manufactured the most effective steel slag roller press which can considerably transform grindabilty of the slag, thus greatly reducing power consumption. Furthermore, this steel slag grinding mill can highly increase grinding efficiency. To illustrate, efficiency increasing index can be 40 or more (K≥40)which presents more remarkable energy saving effect as compared with that of grinding cement clinkers(K=20). Consequently, based on the grinding efficiency, this roller mill is the most ideal equipment for dealing with the steel slag.