- Brief introduction

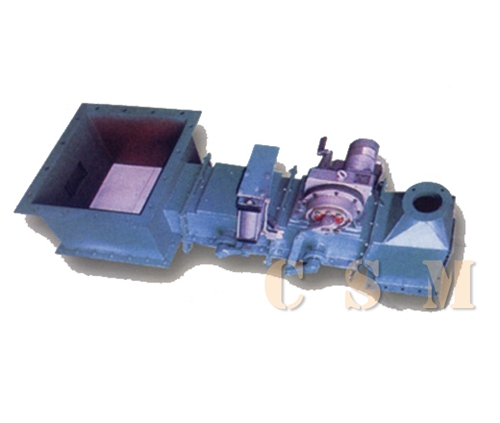

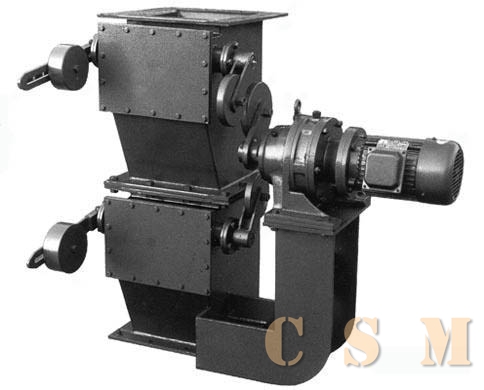

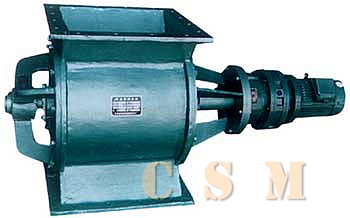

There are two kinds of discharge devices according to the working sites places and working conditions: manual discharging device at bottom silo and pneumatic discharge device at bottom silo. Discharge device at side and bottom silo is mainly used for discharging material of bulk cement silo. It can either be pneumatically controlled or be manual operation with the character of uniform discharging, simple structure and convenient operation.

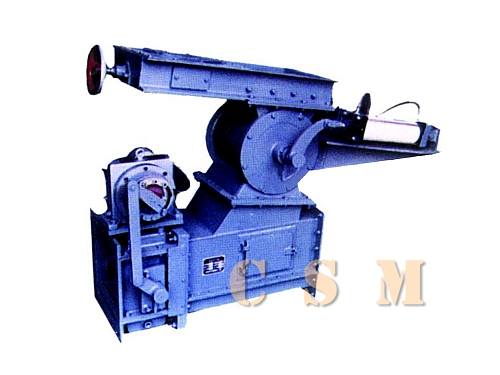

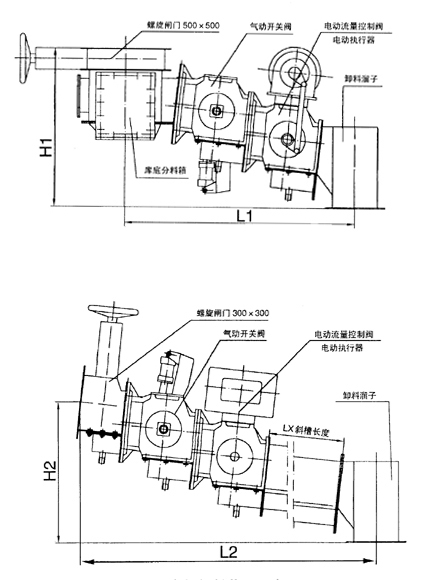

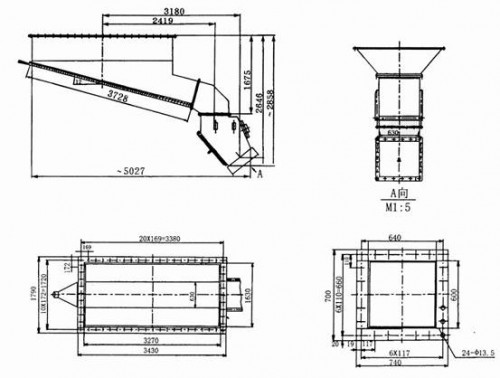

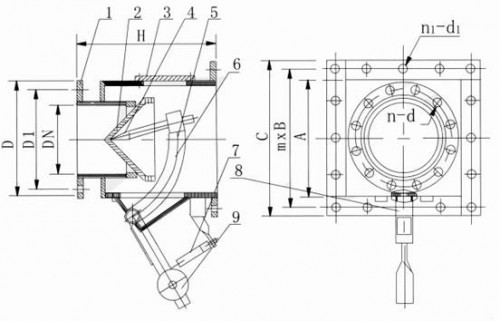

Discharging Device at side and bottom silo

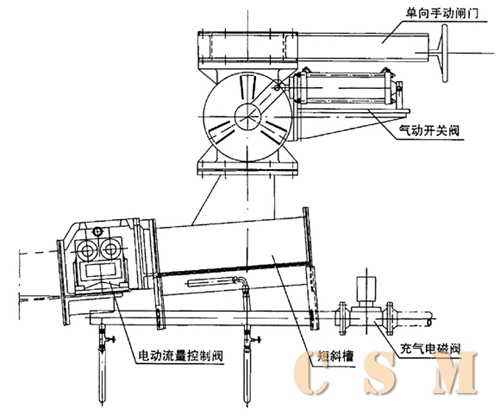

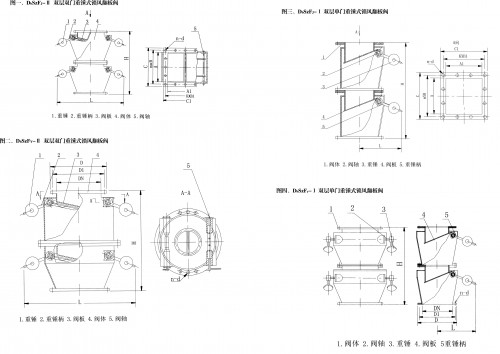

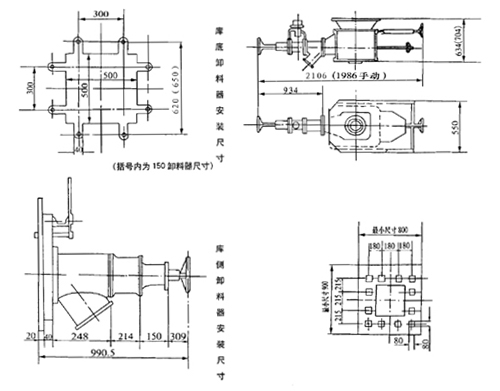

- Drawing

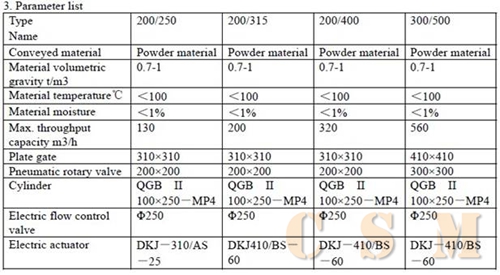

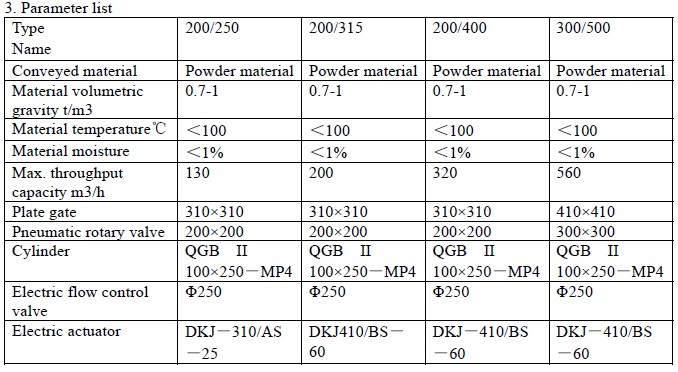

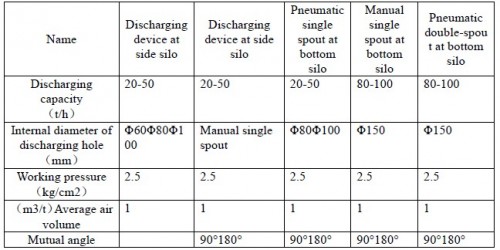

- Parameter list

-

Discharging Device at side and bottom silo