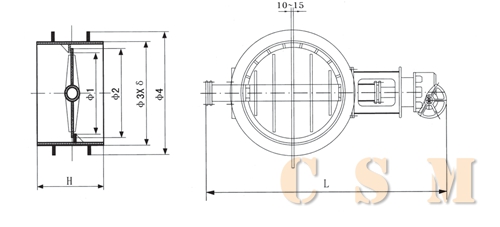

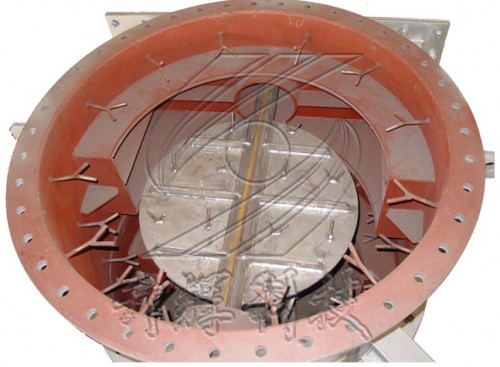

Raw Material Distributor

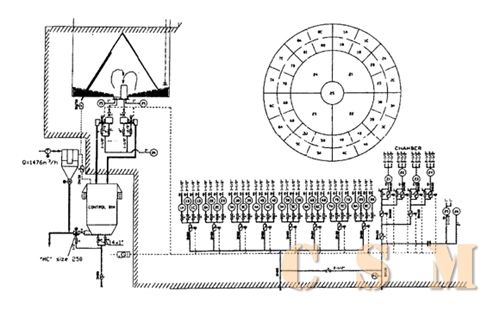

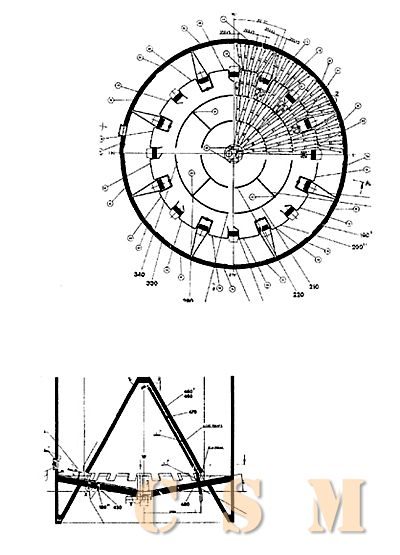

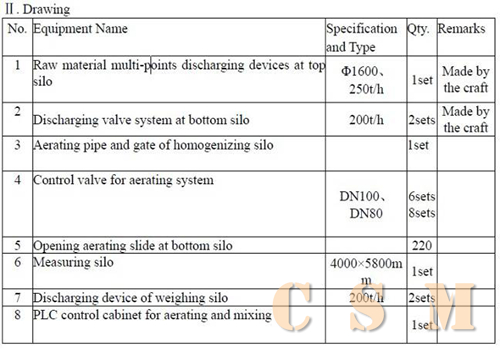

Ⅰ. Brief introduction

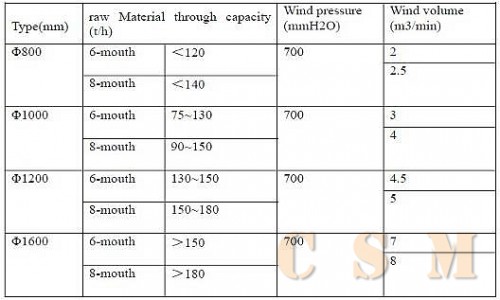

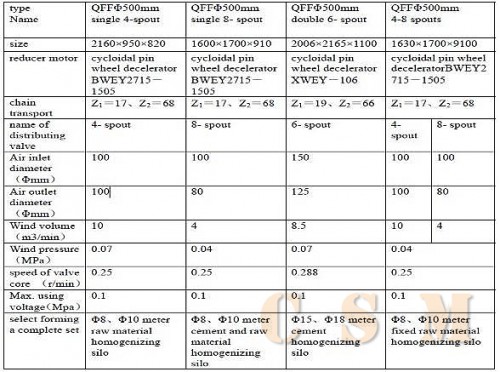

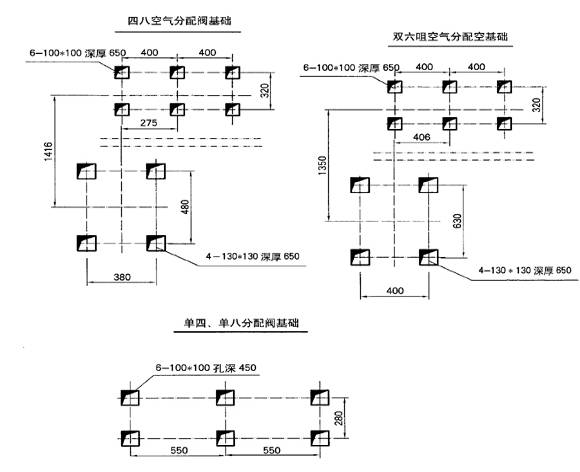

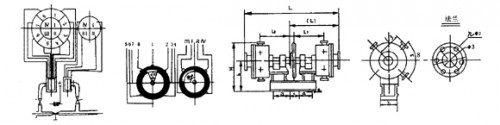

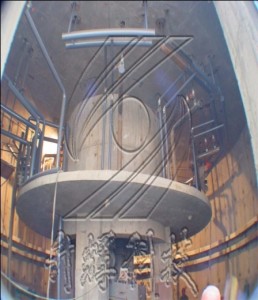

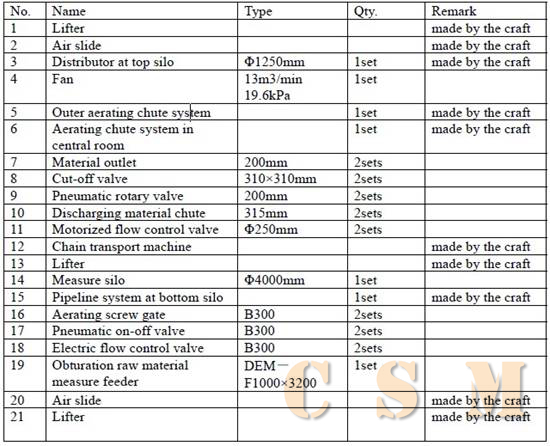

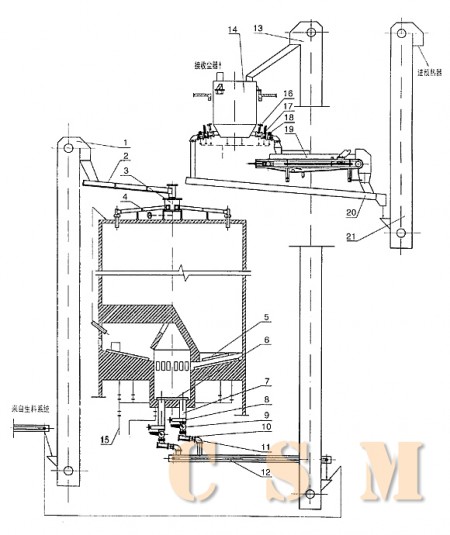

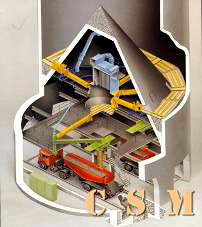

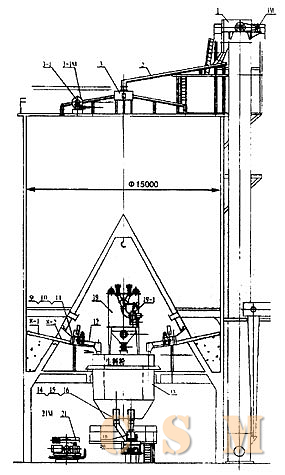

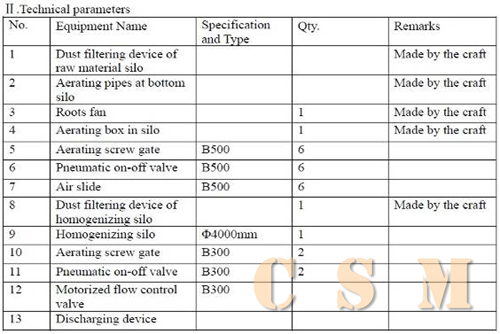

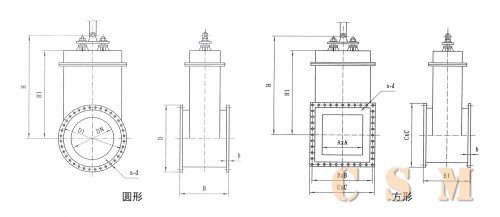

Raw material distributor is a kind of cement industrial pneumatic device, mainly used in the distribution of dry powder material. It is applied to material distribution in the middle part of transport equipment and at on the top of the silo. There is 2-spout, 6-spout and 8-spout production according to the requirement of the production process and the slopes of spout can be chosen from between 6 ° and 14 °. The distributor can be applied to big, medium and small cement factories for distributions of cement and raw material.