PPCAS Plenum Pulse bag filter

Ⅰ.Brief introduction

Plenum pulse bag filter is a high efficiency and advanced filter which is imported from the fuller company of United States. It has not only the advantages which already exist for theseparated room injection and pulse-jet cleaning of various types of bags filters, but also itovercomes the lack of enough strength of room injection and cleaning dust and theshortcoming of same working time for pulse-jet cleaning and filtering, therefore this kind ofbag filter has a wide application field. This type of filter has unique structures and featureswhich could improve the efficiency of dust collecting, and extend the work life of the filter bag.

Plenum pulse bag filter can be used as dust collecting system in the crushing, packaging, the top silo, clinker cooler and various mills of cement factories. If used for dust filtering of grinding coal, an additional flame-explosion-proof facility and a few change of its structure are necessary. it can also be applied for a high dust concentration when dust collecting, such as the grinding system of O-Sepa powder selector in which the gas and dust concentrations are higher than 1000 g/m3 (standard), this kind of dust filter may not need the cyclone filter as the first dust collection. Besides applied in the cement industry, it is also applied to the industries of metallurgical, chemical, machinery and civilian boilers. The material of filter bags is usually made of polyester to allow a continuous use at temperature less than 120 ℃. if the temperature increases, either an alternative materials of filter should be considered, or the exhausted air should be cooled down before entering the dust filter device. Plenum pulse bag filter is used for outdoor.

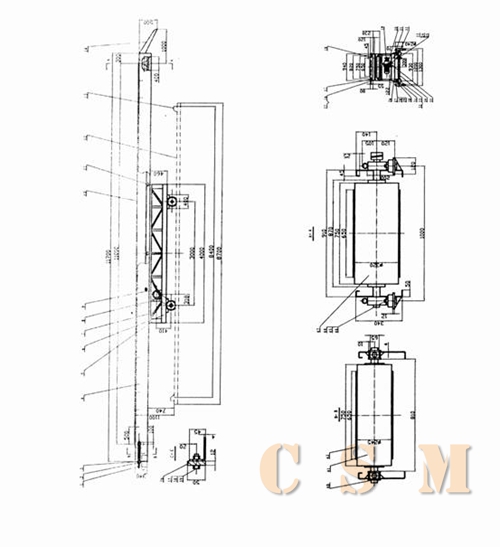

The various specifications are formed based on the combination of different numbers of rooms and bags. Every room has four types of 32, 64, 96, or 128 bags. There are 33 specifications in all and the diameter of the bags is 130 mm, the length is 2450 mm or 3060mm. This Plenum pulse bag filter can work on either negative or positive pressure, and there is no any damage or change for its body structure. The dust collecting efficiency is up to 99.9%, and dust concentration of purified gas is less than 100 mg/m3 (standard). The main technical performances of this series can be found on the appendix. If used in the cold areas with outdoor temperature ≤ -25 ℃, an additional heating system and an additional insulation layer for the shell are needed.

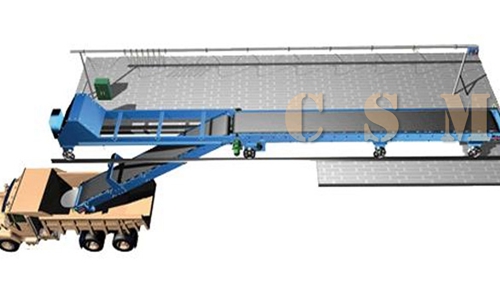

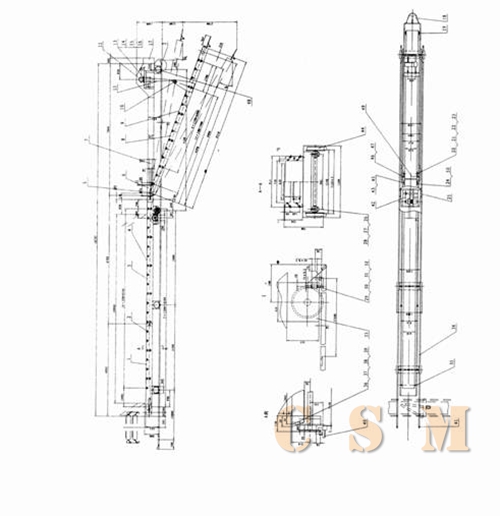

Ⅱ.Structure and working principle

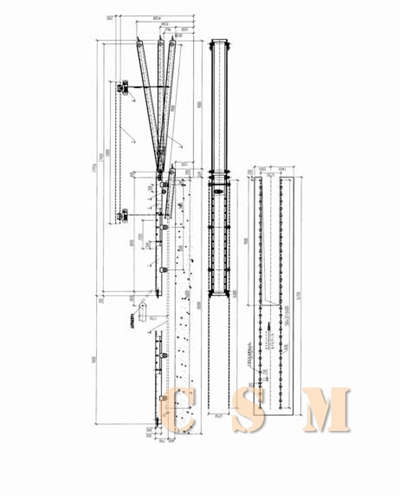

This series filter is composed of the shell, ash bucket, ash exhausting devices, brackets and pulse cleaning system and so on. The dust air firstly hits the inclined plate equipped in the middle of between inlet and outlet when it enters into the filter, then the air flows is diverted to the dust hopper with a reduced speed. The coarse particle dust then falls in the dust hopper directly because the inertia of dust particle plays the role of pre-filter. The gas flow in the dust hopper then goes up and passes through the filter bag equipped with internal skeleton. The dust is caught on outer surface of the filter bag and the cleaned air enters the clean room of the top of the bag, and then is exhausted from the air outlet. The inlet of PPC32 dust filter is equipped on the dust hopper, and the dust flow entering into the dust filter firstly hits the blocking plate at the end of the air inlet, therefore function it has is same as the above. The shell body is divided into many separate filtering rooms using clapboards, dust cleaning of each room is conducted in turn within a given time interval. Every filtering room is equipped with a lifting valve. When cleaning, the lift valve is shut down to cut off the air flow entering into the room. Then the pulse valve opens, and a high-pressure air is injected into filter bags to remove the dust from outside surface. The width of pulse jet and cleaning cycle of each filtering room is controlled automatically and continuously by the specialized cleaning process controller.

Ⅲ.Characteristics

Plenum pulse bag filter is characterized with cleaning dust of each filter room in turn, the so-called off-line cleaning. When injection clean is conducted in a room, the filtering air is cut off to avoid secondary emission from the removed dust. Therefore plenum pulse filter can trap gases with dust concentration as high as 1000 g/m3 (standard).

Ⅳ. Electrical control device for cleaning dust

1.Control mode

Generally the time control method is used as control code. However the limited blocking method is also used to control the different pressure between the inner and outer filter bag. When the different pressure reaches the settings value (normally 1470 Pa), the signal is sent out by the differential pressure transmitter, and then dust cleaning of room by room is conducted by the electric controlling device following the setting procedure.

2. The function of electrical control device

The PLC program controller is applied to the device of centralized control. There are two types of control which are the automatic and the manual. When performance of SCM is failure or SCM is maintained, the control can be switched to manual control. A side machine control is equipped to facilitate debugging and maintenance of the control.

3.The design of layout of electric line from electrical control device of cleaning dust to the terminal of inputting line of filter is decided by the user. The explanation of terminations of inputting line can be found from the specification of electric controller of dust filtering.

·Dust filter system components and supplying

a. Filter body includes shell, ash bucket, filter bags devices, inlet and outlet tubes, dust exhausting devices and ash pulse injection systems (including pulse valves, pipelines, valves, three-connections of gas source, etc.).

b. Dust filter is equipped with electrical control device which works generally with setting time. The orders should show a claim if a resistance control is needed, as the costs of the differential pressure meter of timing controller and the alarm directive of differential pressure and so on is exclusive.

c. Ash disposal device is provided in accordance with the needs of users.

d. If users need different cloth material of filter for some special requirements, or need some additional equipment, for example a heating system is needed when using at the cold region, a specific note is needed directly when ordering.

e. Dust filter can be shipped with complete whole machine or with parts according to different specifications. The basic design of dust filter is decided by customers.

f. The manuals of uses and installations of equipments are provided by manufacturer.