The ends of the ball mill or end do not use the usual main bearing, but using slipper bearing.

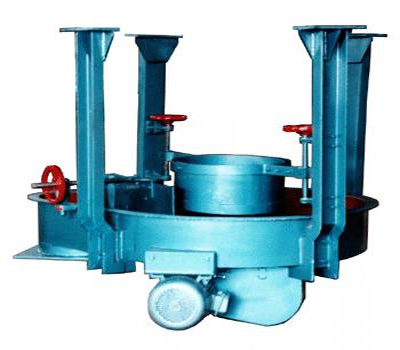

Slipper bearing grinding machine is through the solid loading on the mill barrel belting leather bearing operation on the slipper.

The characteristics of the slipper bearing mainly as the follows:

1) with a sliding shoe bearing mill wheel can have two, three or four, so its structure is not only fully applicable to small and medium sized mills, but without specification limit, you can also use the large mill.

2) using slipper bearing structure, can cancel large grinding machine is easy to damage the grinding head (including the hollow shaft) and main bearing, safe operation, and can shorten the length of the mill, especially the feed end of the mill obviously shortened a lot, reduce cover an area of an area.

3) for drying and grinding mill, due to the cancellation of the hollow shaft, feed off area not subject to the mouth of the hollow shaft, therefore, can be more rational design of the inlet, is conducive to grinding materials and hot air by and reduce the ventilation resistance.

4) due to the mill supporting distance shortened, so the grinding cylinder bending moment and stress reduced accordingly, as a result, the thickness of the steel plate mill cylinder body can be thinned. Especially drying and grinding mill, drying storehouse of cylinder can use thinner steel, reduce the weight of the mill.

5) belting leather linear velocity is much taller than hollow shaft neck, favorable for the formation of lubricating film.

Slipper bearing because of belting leather and shoe of machining accuracy and roughness requirement is strict, so the high cost of the main bearing grinding machine. Slipper bearing structure and maintenance is more complex, once a link in the system failure, require timely detection and repair, it will affect the normal operation of the mill, therefore request furnish corresponding monitoring and control instrumentation.